A bolted steel storage tank is composed of rolled steel tank panels that are connected together via bolted connections to form a vertical cylinder used for the storage of liquid. Today’s prominent bolted tank design is referred to as “RTP”, which designates its “rolled, tapered panel” construction.

The RTP design features panel sizes ~ 1400mm in width by ~2400mm in length. RTP panel construction utilises lap joint panel connections which require exact manufacturing tolerances. When combined with the appropriate sealant for the application, a leak-free connection is maintained between panel connections. Each course of panels connected is called a “ring” and by connecting multiple courses of rings the cylinder is formed. A single row of bolts, along with sealant is utilized to seal each horizontal seam.

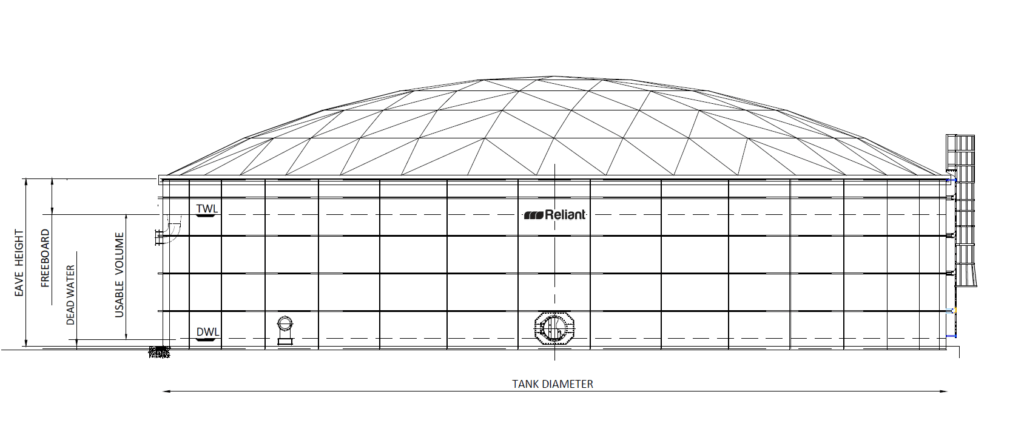

Similarly, the vertical seams are sealed, but multiple rows of bolts may be required to resist design load requirements. Bolted steel tanks are available in diameters ranging from ~3.5m – 95m diameter for liquid storage applications. Prominent bolted liquid applications for water and wastewater storage commonly use an aluminium geodesic dome cover which attaches to the top ring of the bolted cylinder, along with a bolted steel or concrete tank bottom.