Superior epoxy coatings are not created by inventing a fancy, trademarked name for epoxy material.

Superior coating systems are engineered through a combination of product (material) and process (application), supported by decades of R&D, experience and field-tested data.

In order to differentiate one tank coating from another, it’s important to distinguish the facts from marketing fluff.

The coatings technology report is an informational series about coatings and coating processes that will inform you on how to make the best decision on tank coatings, based on your particular technical and commercial decision criteria.

Epoxy coatings are not fused to metal tank panels.

Some tank manufacturers are extremely liberal in their use of the term “fusing” as they apply it to their epoxy coating process and name. Do not be misled by this. True fusing involves the chemical and mechanical bonding of one material to another at the molecular level.

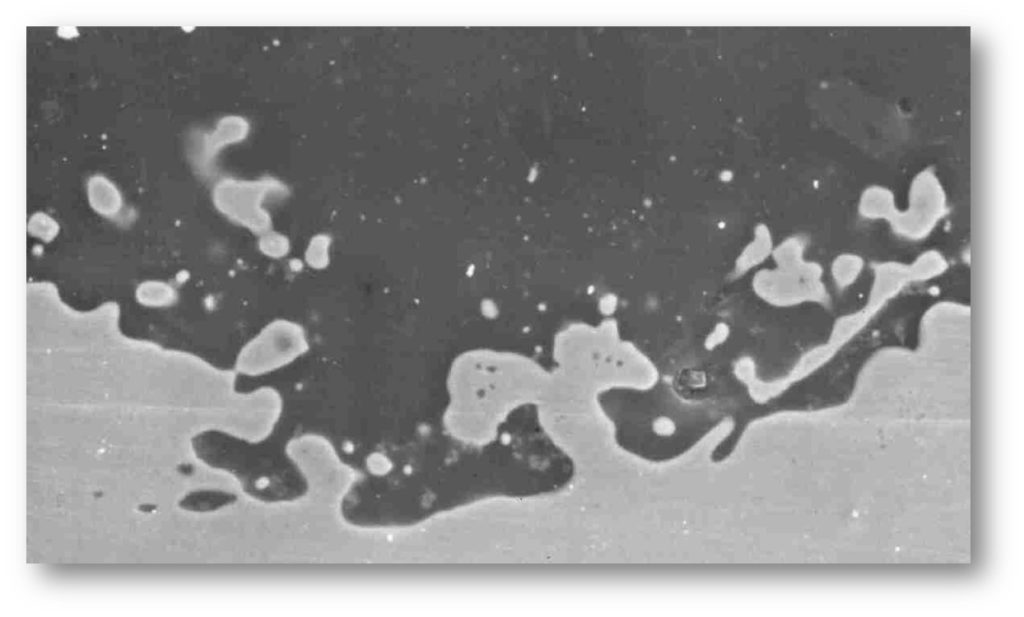

Fusing of a coating to a steel substrate, such as the glass-fused-to-steel enamelling process, occurs at temperatures around 815 °C where the glass and steel molecules become fluid and mix.

Fusing of two materials is evidenced by inspecting the interface between those materials. When fusing materials, the interface is significantly different than either of the two original materials and is indistinguishable due to the change in properties of the steel substrate itself.

Some epoxy coated tank manufacturers will imply that their epoxy coating process involves “fusing.”

Even stretching the use of the term in the epoxy coating process, it can only be used when referring to fusing one layer of epoxy to the other layer of epoxy. It does not involve fusing the epoxy to the steel. In part, epoxy layers are not fused to a steel substrate because epoxy curing occurs at temperatures only around 270 °C

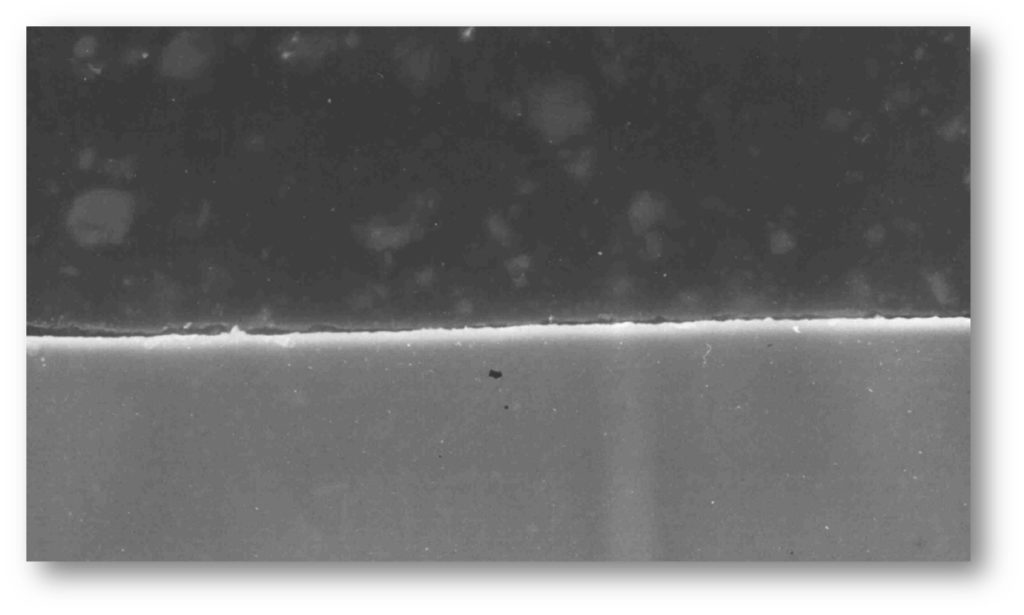

These lower temperatures are primarily used to accelerate the epoxy cross linking and reduce drying time. They do not create a “fusing” environment or even approach the temperature where the molecular structure of steel changes. The lack of fusing the steel substrate to the epoxy layer is evidenced by a clean visual line between the two layers of powder and the steel substrate (such as in Figure 2). Figure 3, in contrast, shows the virtually indistinguishable boundary between the liquid and powder epoxy coatings.

Our glass coatings are both chemically fused to and physically combined with the steel substrate. This results in an unmatched, tough and durable bond that will exceed any other coating.

Reliant Solutions specialise in design and construction in Glass Fused to Steel bolted steel panel tanks. To learn more about our designs and fusion process refer to our Glass Fused to Steel page or refer to our supplier’s website www.permastore.com