Project

Gore wastewater storage

Case study

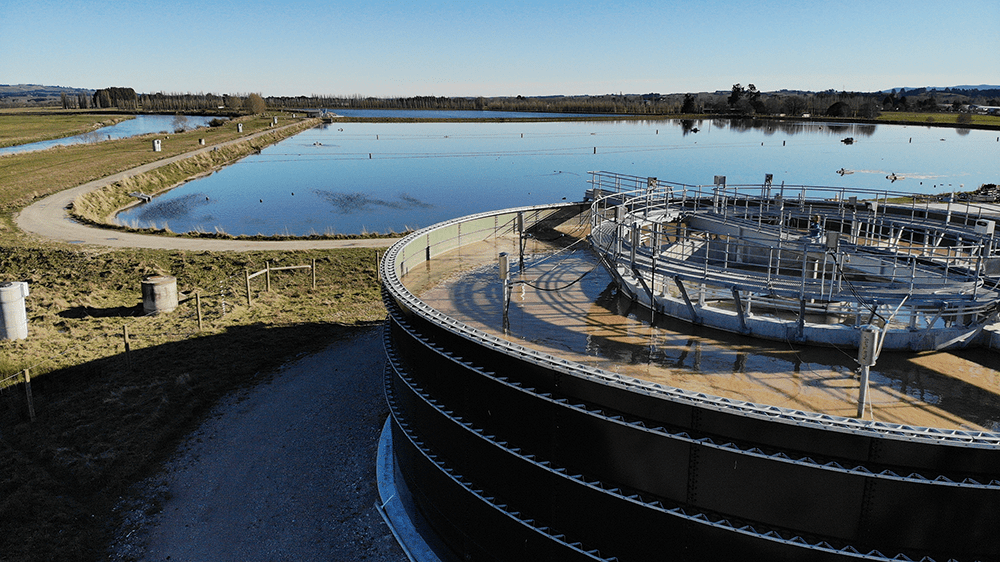

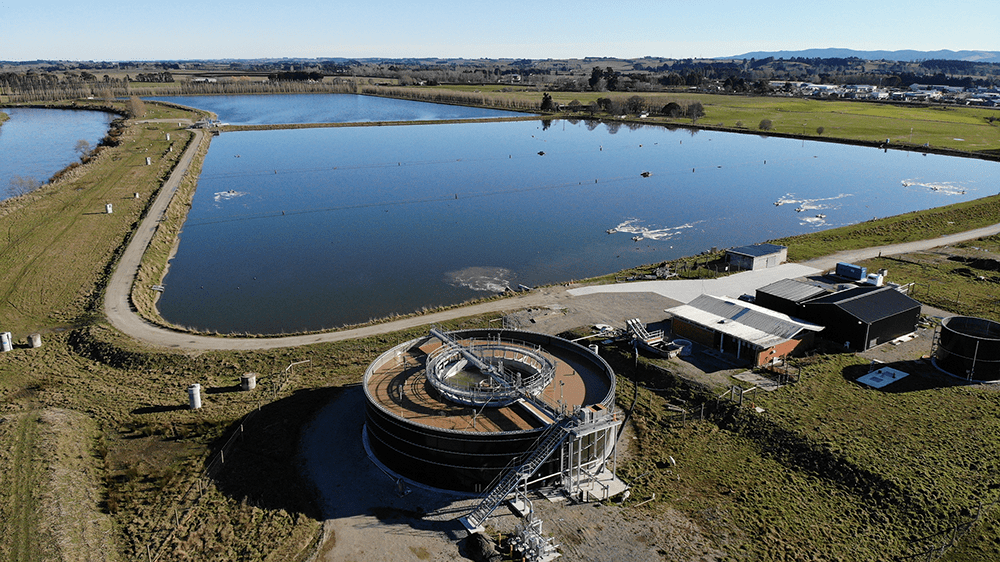

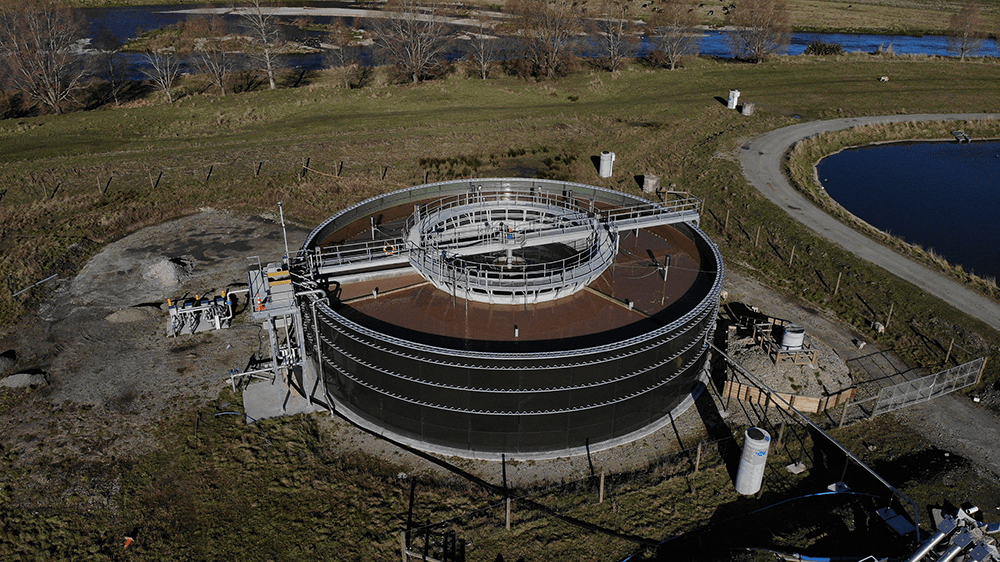

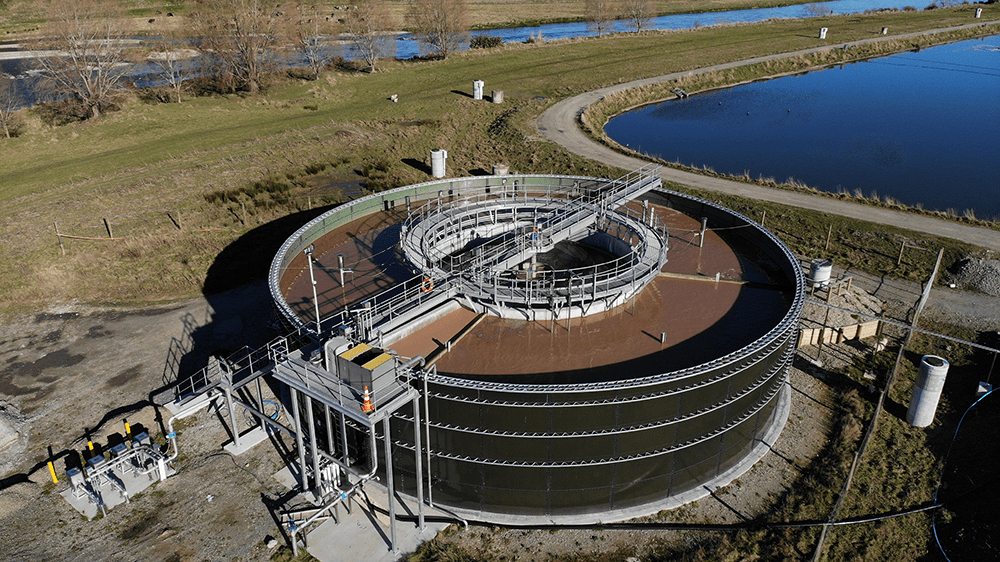

Reliant Solutions delivers on Gore wastewater storage

Overview:

Reliant Solutions was contracted by project managers Signal Management to undertake the design and construction of the new wastewater treatment storage tanks for the Gore District Council 3 Waters treatment plant upgrade.

Story:

The development of the $240 million Mataura Valley Milk project near Gore included a significant upgrade to the town’s wastewater treatment plant – and Reliant Solutions was on hand to provide the extra storage needed.

Reliant Solutions supplied the storage for the treatment of the wastewater in the form of high corrosion resistant Glass Fused to steel tanks that are great for effluent treatment.

Mataura Valley Milk invested several million dollars to build the upgraded wastewater treatment plant near Gore. It is a joint initiative involving the Gore District Council.

The plant has been specifically designed to treat wastewater from Mataura Valley Milk’s purpose-built nutrition plant at McNabb, about 5km north of Gore.

The plant is one of several facets to the $240 million nutrition plant development where the company and the council are working collaboratively.

The council’s existing wastewater ponds did not have the capacity to cope with increased loading from Mataura Valley Milk.

The new plant was built next to the council’s existing wastewater treatment ponds in south Gore, and is one of the most sophisticated plants in the south.

The company’s investment into the district’s infrastructure made sense by providing a solution for Mataura Valley Milk, while also upgrading the domestic wastewater treatment capability for the Gore district.

Mataura Valley Milk pre-treats the wastewater on-site, before piping it about 6km to the industrial hub, where it is treated again before discharge.

Scope of work

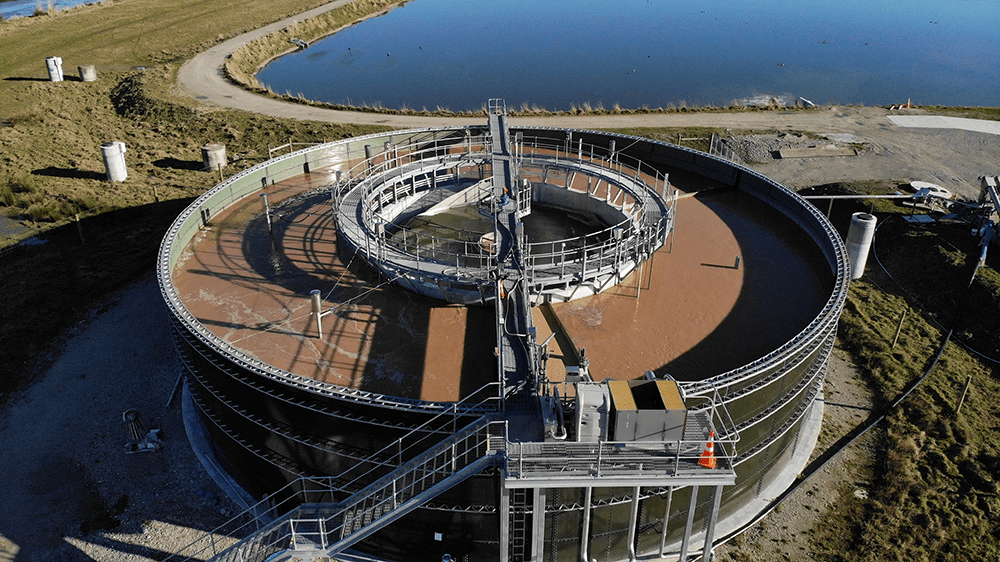

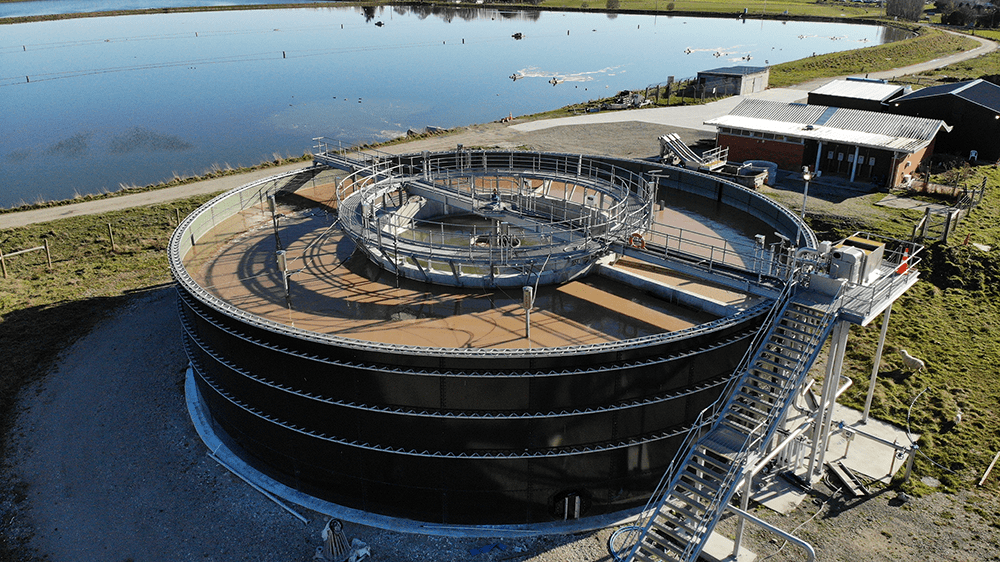

Tank#1 – Clarifier Tank

Design Specs

Application

Wastewater

Tank Type

Glass Fused to steel

Diameter

27.32m

No. of Bolts

12,454

Height

6.34m

Capacity

3,640,700L

Scope of work

Tank#2- WAS Tank

Design Specs

Application

Wastewater

Tank Type

Glass Fused to steel

Diameter

8.54m

No. of Bolts

3,921

Height

5.673m

Capacity

316,000L

Benefits of Bolted Tank Technology:

All tank parts are factory coated for maximum protection and are easily transported to the job site.

Bolted tanks can be erected in 1/3 of the time required to build a field-welded or concrete tank on-site.

Tanks can be assembled in even the most remote sites, without large staging areas, and in every season of the year.

Bolted tank construction is very eco-friendly with little disturbance to the surrounding environment.

Our bolted tanks are factory coated, so there is no in-field painting required, which can expose the environment to harmful silica